We have all seen the backlogs of container ships in California. They are anchored near the Ports of Los Angeles and Long Beach or drifting nearby. Waiting. The reasons for the wait, sometimes weeks long, are varied and complicated. The solution to this backlog, likewise, is complicated and multi-dimensional.

We at Pacific Maritime Group are proud to be involved, in an indirect way, in solving the backlog. If a container ship needs a berth to unload its valuable cargo, build a berth. Or in the case of the Port of Long Beach Pier G, add to one.

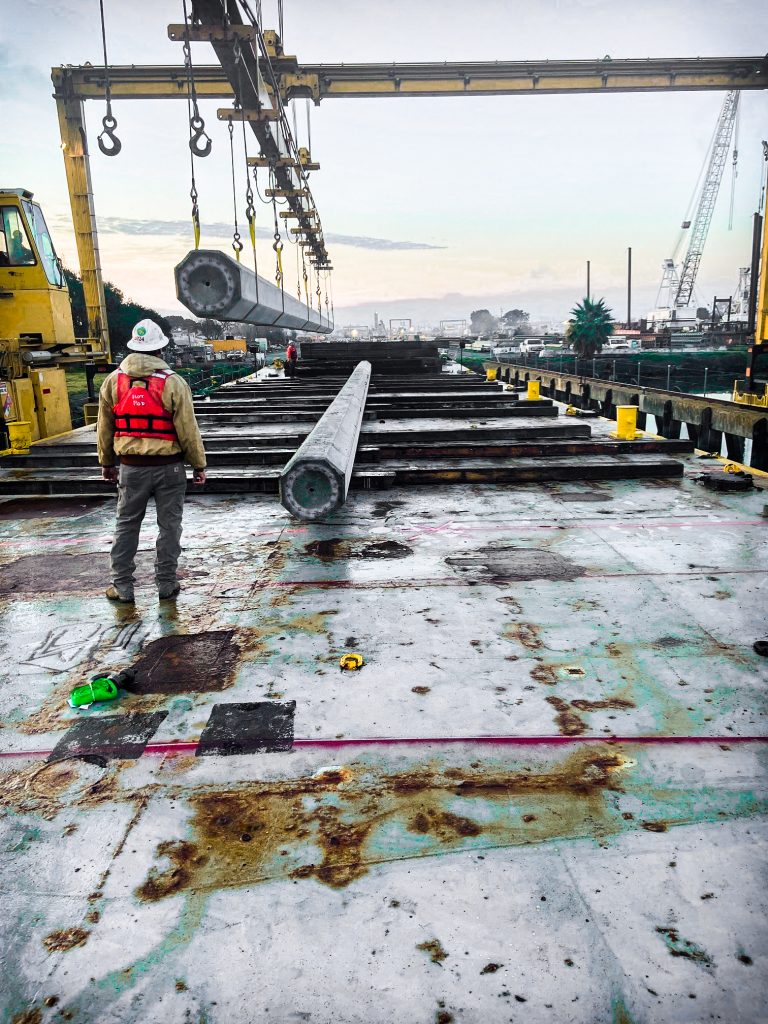

Dutra Group of Rio Vista, California has a contract to do just that. Over the next few months they will be adding approximately 250 feet to Berth G-235. They will be driving piles and building deck and apron to handle the massive cranes, haulers and forklifts that pluck a container from a ship and deliver it to a truck or rail. PMG is transporting the piles to the job.

These are carefully engineered reinforced concrete piles nearly a hundred feet long. Each one weighs over twelve tons. Imagine a hundred and fifty of them. A line of trucks as far as you can see.

But we don’t do trucks. We do barges. In this case, ABS certified ocean barges. We used the deck barge PTS-1 plus the ramp barge PTS-185. Both barges were towed by the PMG tug KATHERINE. This tandem tow went from Long Beach to Antioch, California and back. In Antioch the barges were loaded with piles at Kiewit Construction’s Kie-Con yard. This was where the pilings were built. Then each one was carried aboard and set carefully onto the barge deck.

More were added, in a careful pyramid shape, each protected by wooden timbers. The PTS-185 carried 44 piles and the PTS-1 carried 32. In total each barge was loaded with more than a thousand tons.

The KATHERINE towed them from Antioch to Long Beach and did it again. Two trips, four barges. Add it all up and it equals one more construction job, one more part of a very big solution to this very big problem.